You are here

Manufacturing Students Prepare for the Real World

In early May, eight QCC manufacturing students presented their capstone projects to the public in an informal demonstration that showcased the products they had worked on for the semester. According to Damian Kieran, Associate Professor of Manufacturing Technology, this is a class that the students take near the end of the manufacturing program to try and create as much as possible, a real world situation and end result product. The students dealt with deadlines as they would in a real world setting.

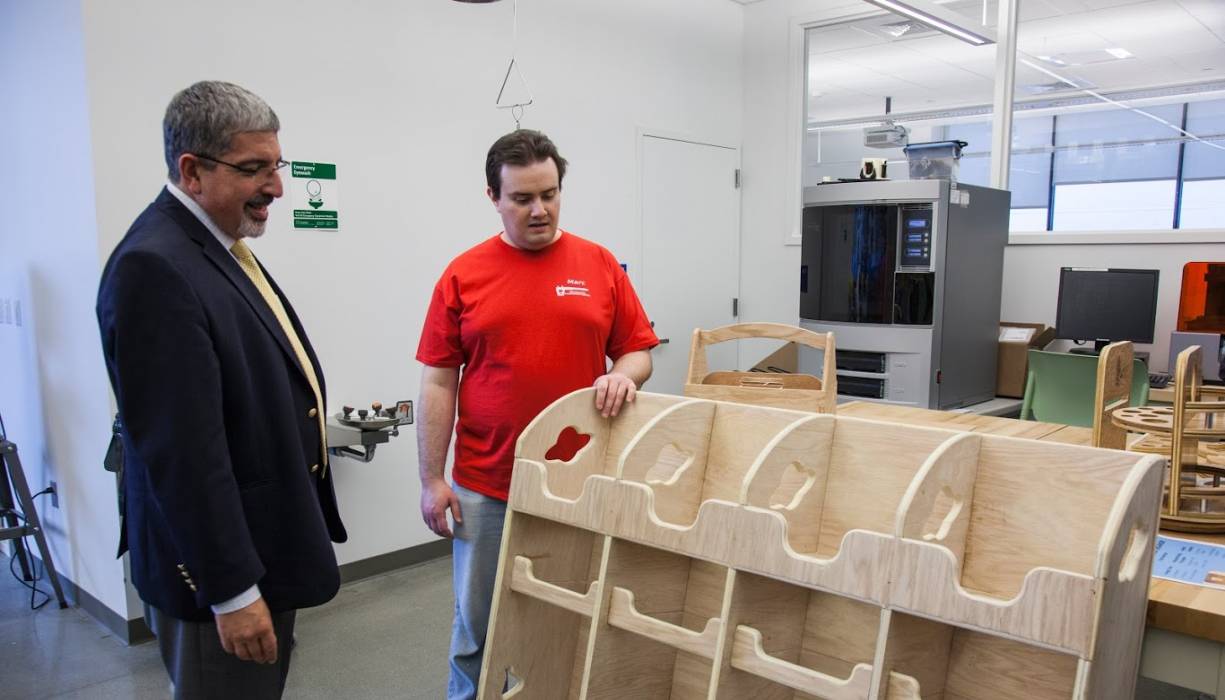

Projects included a student who did an injection molding project and made a case for a USB memory stick; two woodworking projects using a CNC router; a T-shirt project that utilized the Fab Lab’s new embroidery machine and a 3D printer project, which was an extension of last year’s 3D project.

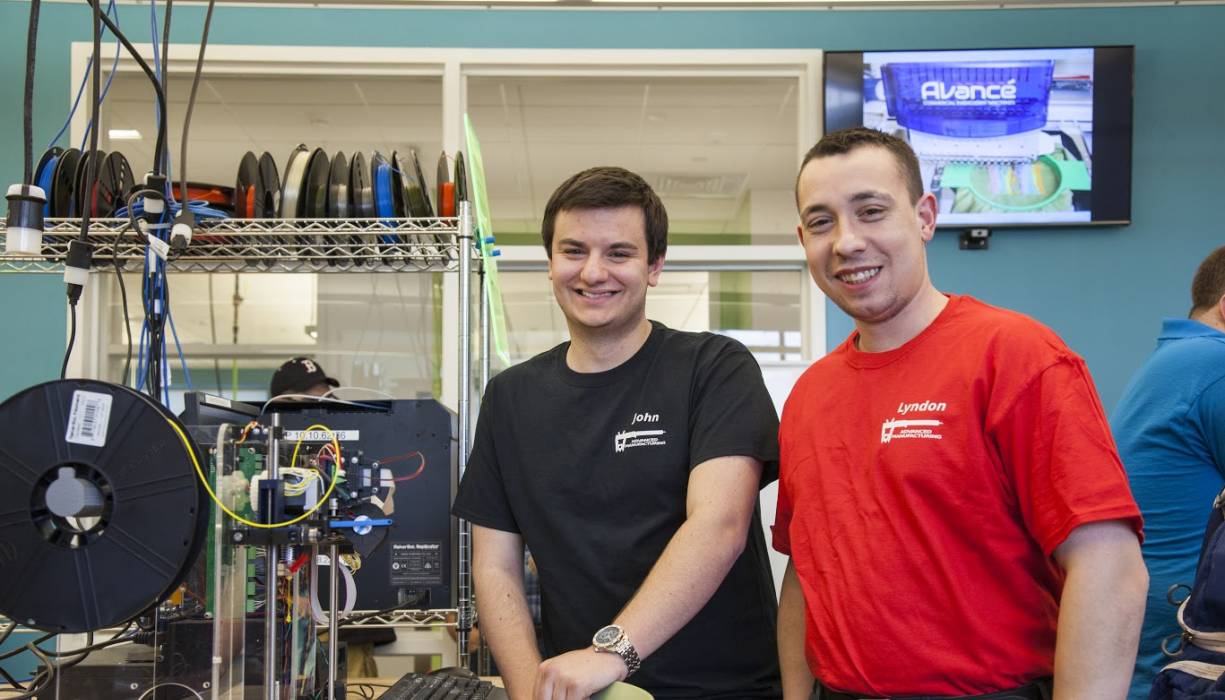

Manufacturing student John Carmody took an existing 3D printer that was made by last year's manufacturing students and upgraded and improved it by adding a thicker frame to make the printer sturdier; tightening up the electronics and putting a protective cover around it.

“Every one of these students delivered real-world products at the end of the semester,” said Associate Professor Kiernan. “I’m very pleased with how these students handled this project for the entire semester and I’m very pleased with the outcome.”